Internal combustion engines are the main source of propulsion not only for cars, trucks or buses, but also for many types of machines. During their work, fuel is burned, and the side effect of this process is the release of many harmful compounds into the atmosphere.

Automotive concerns were aware that it was necessary to reduce their number. Initially, technical means were used for this purpose, whose operation was regulated by legal norms. One of the solutions used was the afterburning process. Thermal reactors have been located behind the outlet valves in which oxidation of hydrocarbons and carbon oxides took place.

In later years, the ecological awareness of people gradually increased. It began to be noticed that the solutions used were not sufficient. Therefore, catalysts have been introduced.

Catalysts have a very important function in the exhaust system. Their task is to clean car exhausts from toxic substances such as carbon oxides, nitrogen oxides and hydrocarbons.

In order to be able to carry out this task, precious metals contained in them are necessary – platinum, palladium and rhodium. It is they who perform the correct catalytic function. Due to their presence, the chemical composition of the exhaust gases that escape from the combustion chamber differs from those that escape from the exhaust pipe.

How are they built?

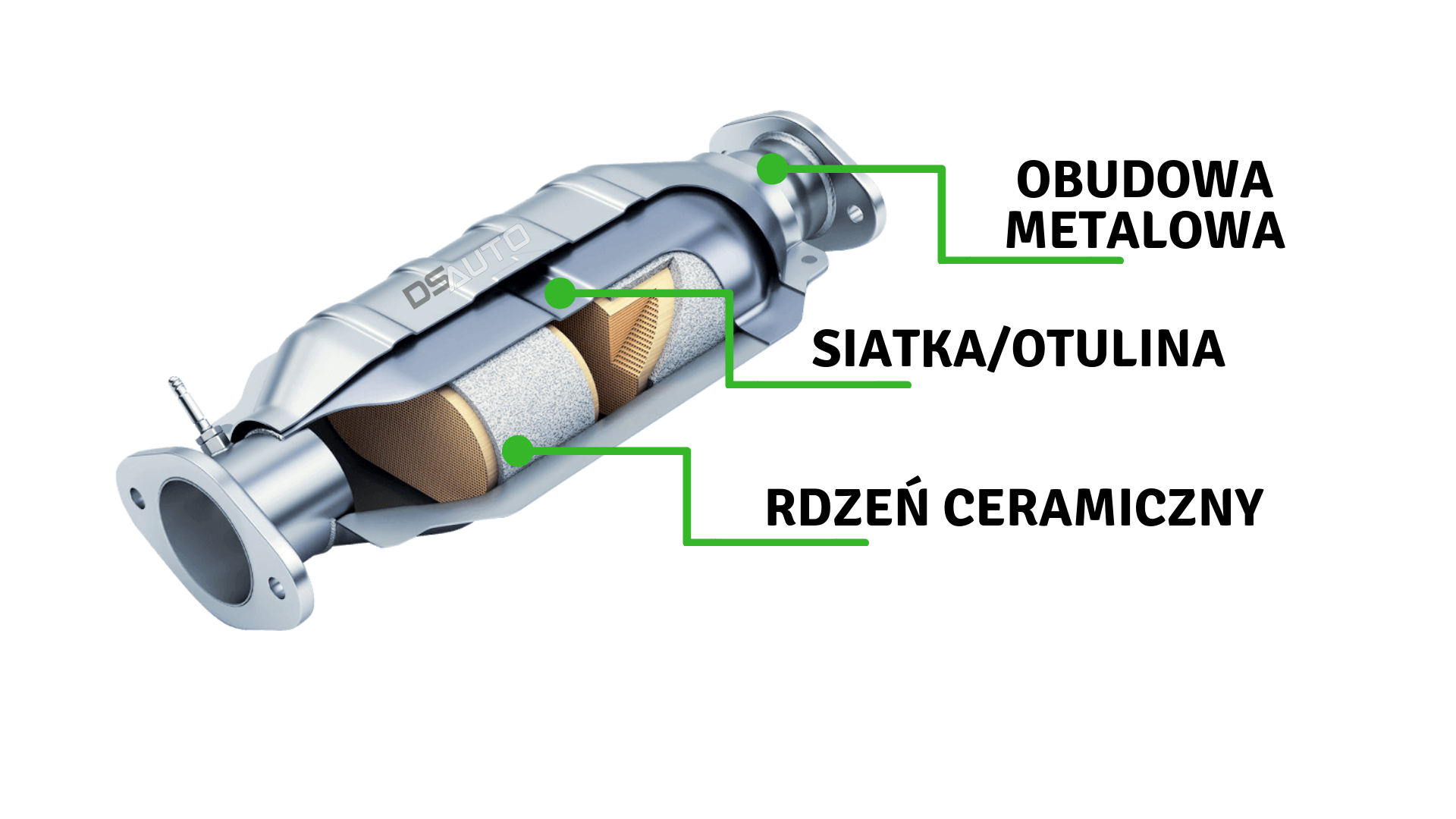

Catalysts consist of the following layers:

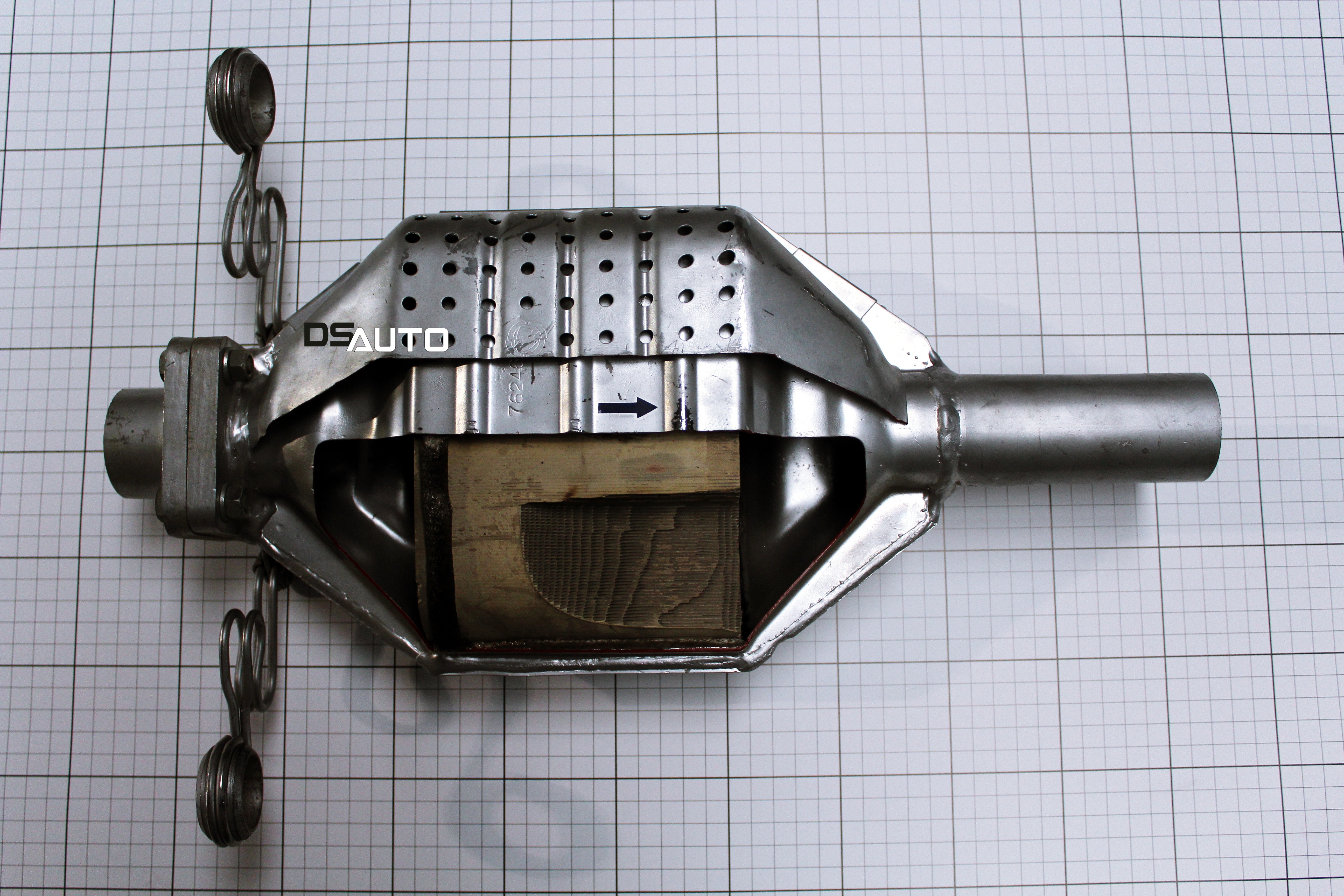

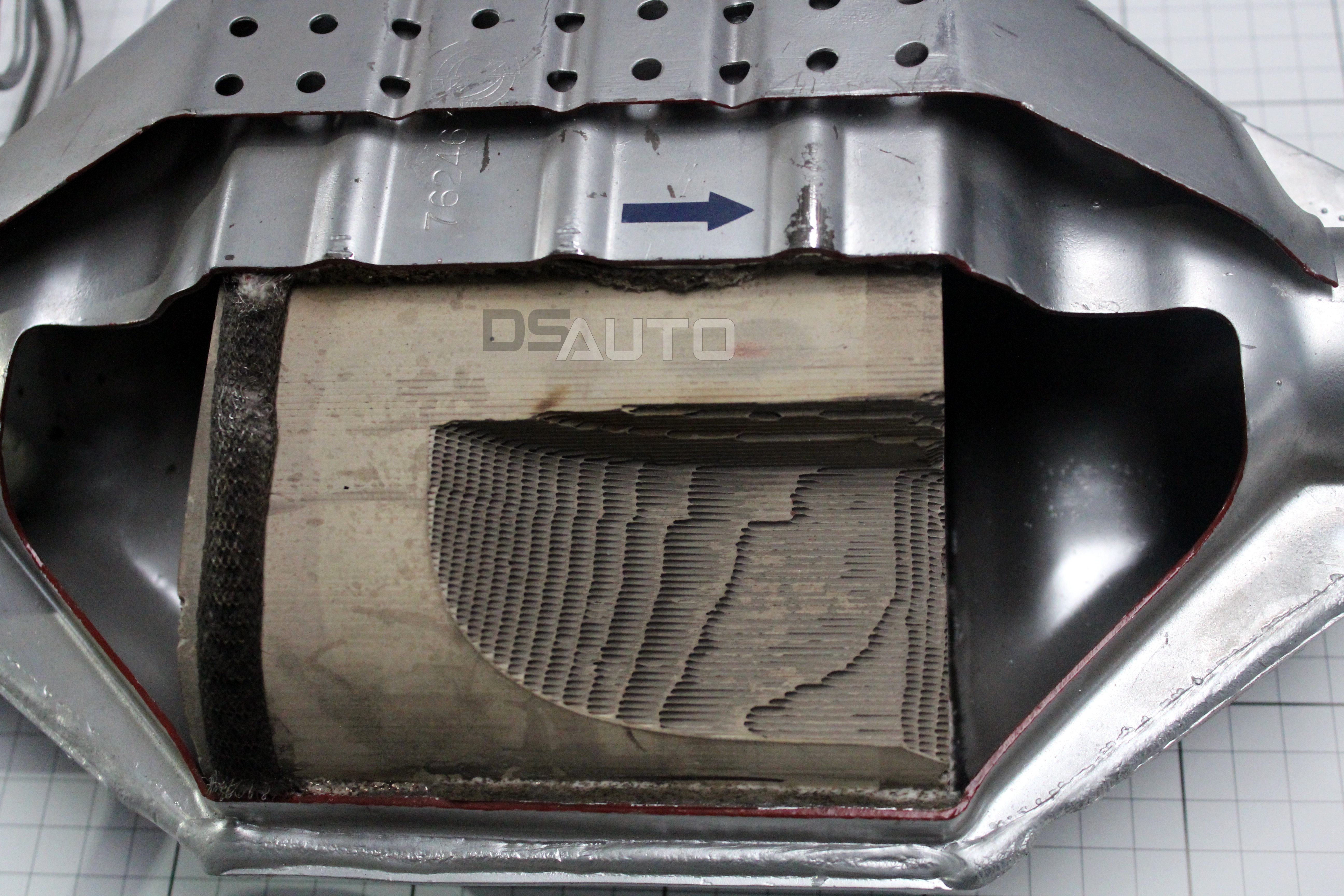

A metal casing, which is the first, outer layer; mesh / lagging, whose task is to protect the monolith; and the ceramic monolith itself.

The cross-section of the catalyst can be illustrated on the example of the Fiat model.

Operation of catalysts

Harmful combustion products are reacted by the oxygen present in the exhaust. This creates pure nitrogen, water vapor and carbon dioxide, which is less dangerous than its oxide. Oxidation depends to a large extent on the appropriate temperature. The time, which is available for natural oxidation, without any external support is extremely short. Not all toxins will burn.

That is why it is necessary to mount catalysts. Their role is to guarantee conditions that will increase the intensity of reactions neutralizing toxic substances.

There are two types of reactions resulting in the purification of exhaust gases: oxidation and reduction reactions. As a result of oxidation, hydrocarbons and oxides of carbon react with oxygen, thanks to which we get CO2 and water vapor. On reduction, nitrogen and carbon oxides enter a reaction that produces nitrogen and carbon dioxide.

Types of catalysts

There are basically two main types of catalysts on the market – metal and ceramic catalysts. The latter are much more common.

The metal catalyst is made of extremely thin, metal tape, made of heat-resistant, chromium-nickel steel. Aluminum admixtures are also used in their production. The tape is covered with a corrugated ribbon containing a layer of precious metals. In the production of 1 catalyst, about 1.5 g of the alloy is used.

Benefits:

+ faster temperature reaching appropriate for the cleaning process

+ high mechanical strength

+ resistance to large temperature changes

+ longer life of parts

+ lower flow resistance

Disadvantages :

– higher price

It is for this reason that these catalysts are assembled less often and usually in more expensive cars than catalysts with a ceramic insert.

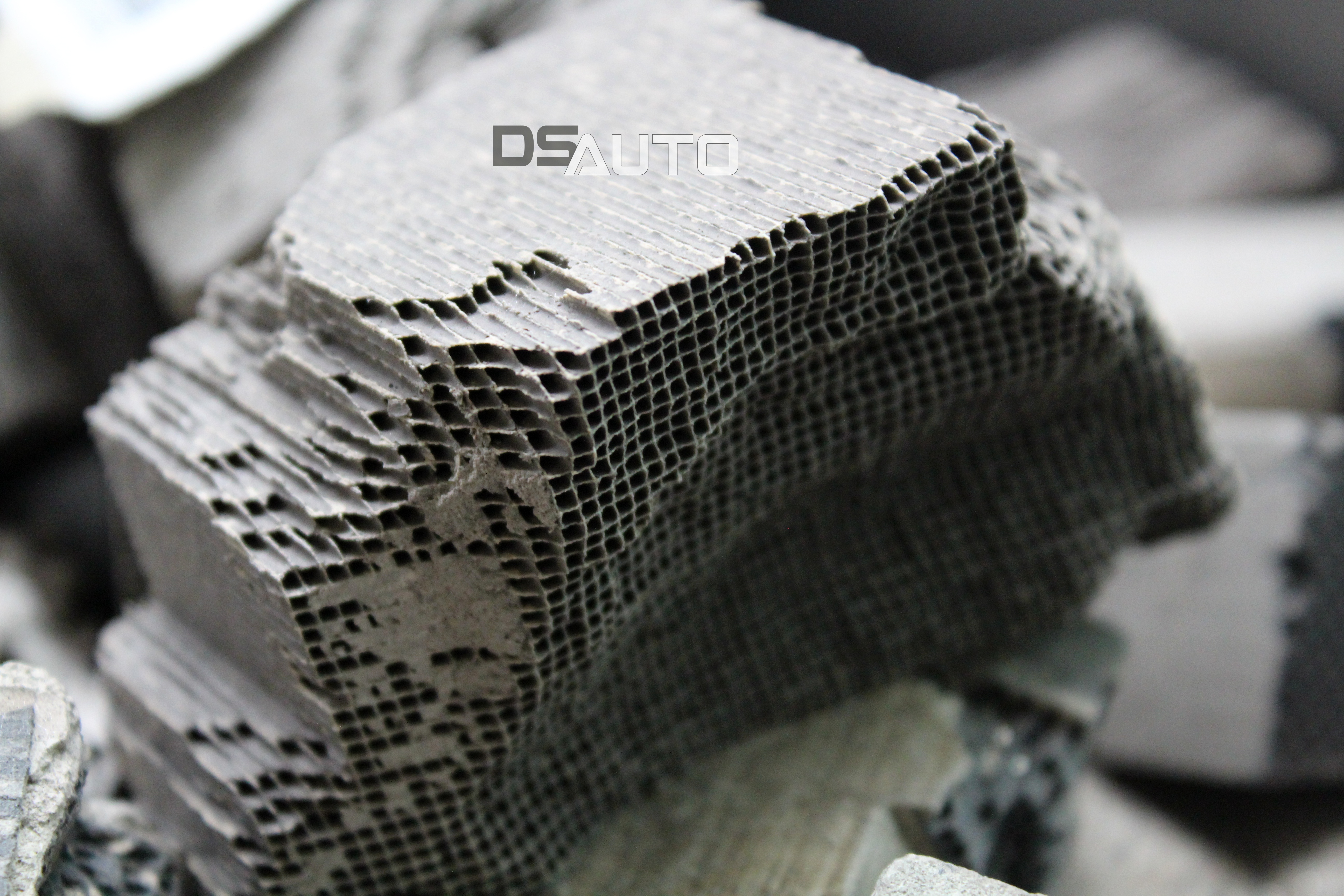

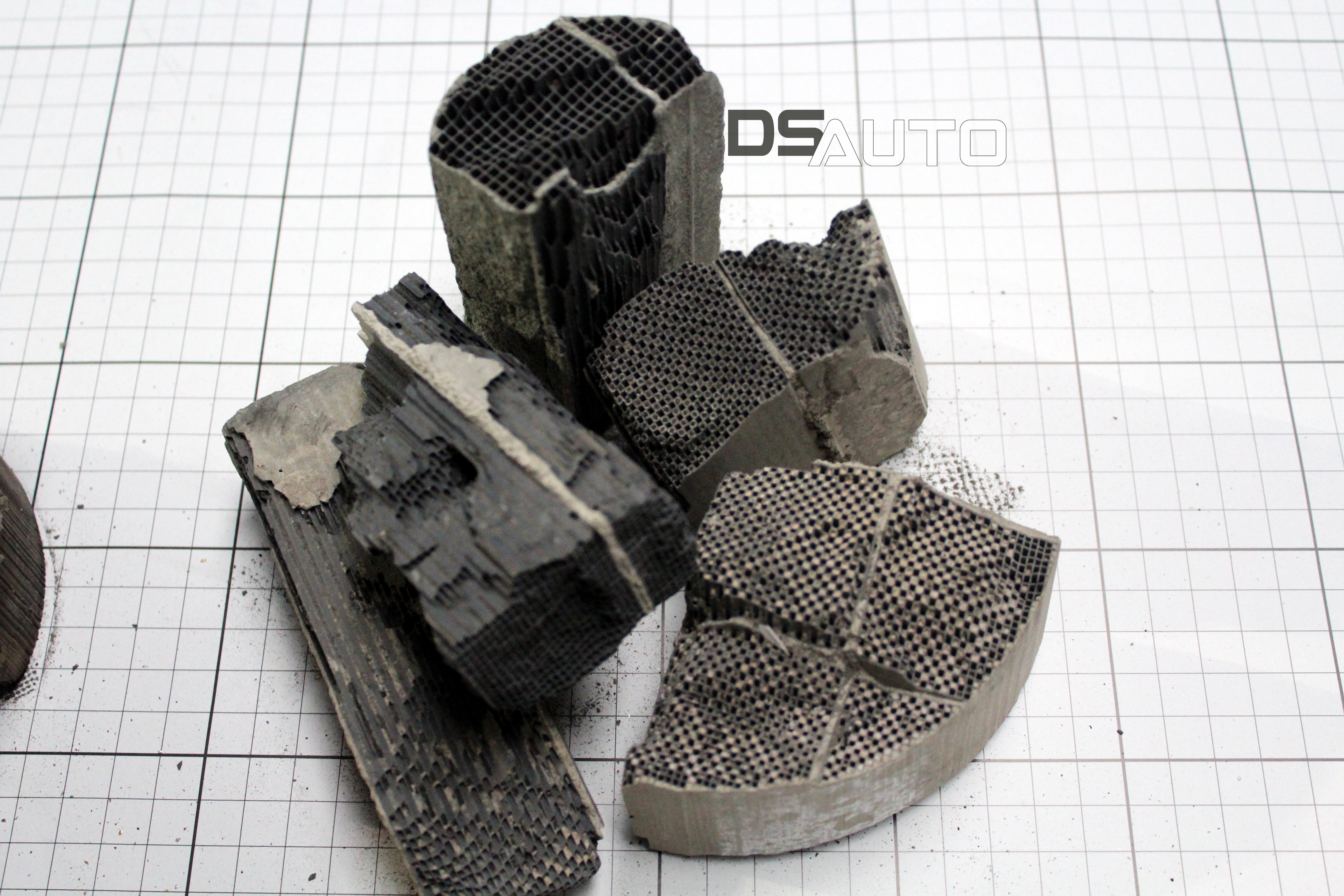

Catalysts with a ceramic insert, in turn, are built of block ceramic core – so-called monolith. It has a structure resembling a honeycomb. This structure is formed by channels covered with noble elements.

It is worth emphasizing here that the purification requires not only gas combustion products, but also produced solid particles. A big problem with self-ignition engines is the soot particles that are dangerous to our health. In this case, you do not need chemical and mechanical filtration. Solid settle on porous fibers, thanks to which they can be “burned” in it.

Due to the way they work, they are susceptible to clogging, and thus require frequent regeneration or – if it is impossible – replacement.

Very often it is possible to find combined devices in which the particulate filter is mounted together with the catalyst. This allows simultaneous purification of gas fumes and solid contaminants.

At DS AUTO we buy not only complete catalysts. We also accept the insert itself (metal or ceramic), and a monolith in any form – whole, in pieces or in powder.

Regardless of the character, thanks to the fact that we have experienced staff, professional machine park and our own laboratory, we are able to make a precise analysis of the precious metal content in the delivered material, properly priced and processed.

It is also our responsibility to properly prepare the monolith for testing. Weigh and describe, grind in ball mills and bring to a uniform, homogenized form and take a sample for testing.

The test is carried out using spectrometers. In our everyday work, we use the ICP MS device and Olympus spectrometers.

As you can see, in the case of purchase of the metal cartridge itself, ceramic monolith in pieces, powder or DPF filters, recognition and valuation require appropriate equipment as well as specialist knowledge and experience.

We invite you to use our services. How to sell a monolith?

Make an appointment and free monolith quote – over 100 kg

Tel. +48 604 611 917

E-mail: dsautospzoo@wp.pl

For smaller quantities, we invite you to our partner retail purchases.

Phone number:

Phone number:  E-mail:

E-mail:  A stationary point:

A stationary point:  Getting from the customer:

Getting from the customer:  XRF analysis spectrometer:

XRF analysis spectrometer:  Valuation by numbers:

Valuation by numbers: