Today, we would like to summarize the year 2018 in terms of the amount of used catalysts that have collected companies operating in individual voivodships. Not only catalysts from passenger cars, but also from trucks, buses, motorcycles or machines were taken into account.

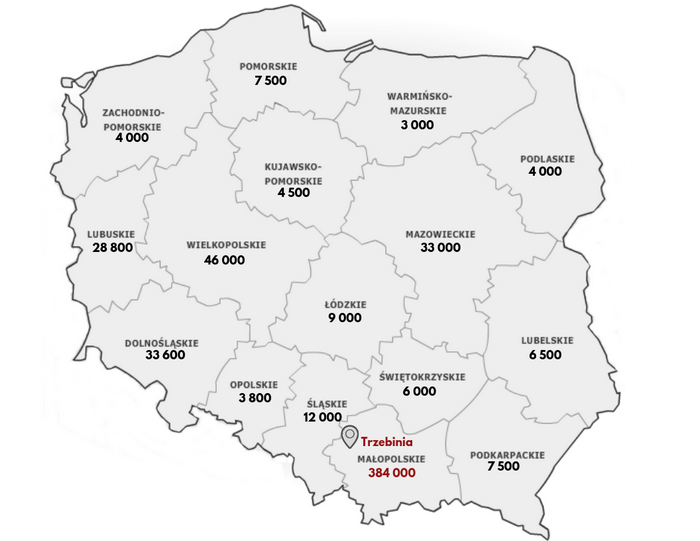

The following figure shows the annual sum of collected catalysts.

As you can see, the Małopolskie voivodship was ranked first with the DS Auto capital group, which includes the largest catalyst converter in Poland – Unimetal Recycling Sp. z o.o.

The amount we have collected is impressive and amounts to 384,000 catalysts code 16 08 01 and 16 08 03. The second place was taken by companies from the Wielkopolskie voivodship with the number of 46 thousand, followed by the Mazowieckie voivodship, in which the purchases recorded the value of 33,000. pieces.

Noteworthy is the Lubuskie Voivodeship, in which the number is less than 29 thousand used devices.

Where did we get the good result we achieved?

In spite of the less favorable location than in the case of voivodships with a larger number of inhabitants, such as Mazowieckie, Śląskie or Wielkopolskie, we found ourselves in the first place in the ranking.

Our position and the number of catalysts that we buy and recycle primarily results from the fact that as the only company dealing with it, we have such an extensive network of partner collection points throughout the country. These points deal with retail quantities, while we accept wholesale deliveries from the largest dismantling stations in Poland.

All points with which we have the pleasure to work are trustworthy stores that enjoy a good reputation among the sellers. We are aware of how much we can do together and how much this cooperation is building up for everyone. When we hear flattering opinions that thanks to us someone’s company has developed and is successful using our solutions, we know that all this makes a huge sense, and our persistent work is not in vain.

In addition, we use the best valuation tool – CatCatalog‘s largest online catalyst database, with over 7,700 models. Thanks to this tool, collection points that want to develop and operate professionally, can implement this plan. Without such support, they would have to equip themselves with expensive equipment to analyze the precious metal content and analyze all the models they want to adopt. We did this work for them.

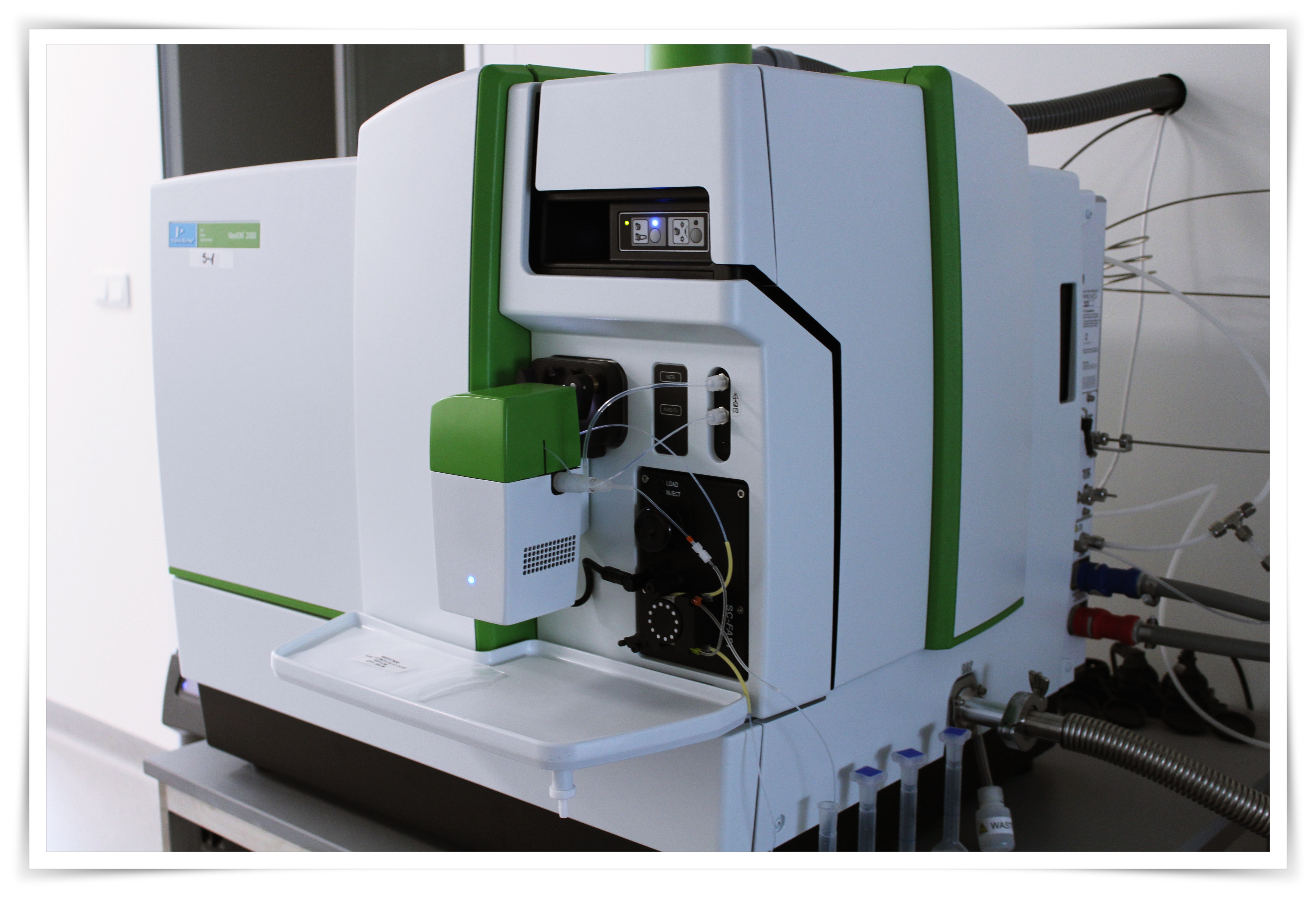

What distinguishes us on the market is also our own laboratory. Thanks to it, our offer is complete and contractors avoid participation of agents in the whole process. We can therefore offer you the best possible prices. The analysis takes place on site, and in addition it is public, so anyone who would like to cooperate with us can observe how we work. We have no secrets for you.

The strength of the laboratory lies not only in the technology used – certified spectrometers that indicate the real content of precious metals in the material. Its reputation is primarily determined by the people who create it. They are the best qualified specialists with vast knowledge and practical experience. Having expensive and good equipment will not be a success in itself. It will definitely help, but it is not enough. The most important are people who have the right skills and knowledge to use it. The laboratory is equipped with certified stationary spectrometers such as ICP MS, which is undoubtedly the best position on the market at the moment, and portable spectrometers of the recommendable Olympus brand.

What we can offer as one of the few companies is the transport of waste. At one time it can be up to 24 tons. If you are planning such a large delivery, we encourage you to contact us. We have all the required permits, both for the needs of transport and for the collection or processing of waste with the codes 16 08 01 and 16 08 03. We can therefore cooperate in the purchase of all types of catalysts on the market.

It is also worth mentioning the modern hall, equipped with a reliable machine park, which consists of machines for cutting catalysts and monolith recovery and precise ball mills that grind the monolith, to obtain a granular material with appropriate granulation, which is transferred to the laboratory. Good equipment and experienced professionals are the best possible combination.

The last – possibly the most important – reason for our place in the ranking is the satisfaction of people with whom we work and whom we have never let down. It is thanks to the trust you give us that we have achieved so much.

Thank you to everyone for cooperation in 2018. We do everything to make this year equally fruitful.

Contact us to cooperate with us!

Tel. +48 604 611 917

dsautospzoo@wp.pl

Phone number:

Phone number:  E-mail:

E-mail:  A stationary point:

A stationary point:  Getting from the customer:

Getting from the customer:  XRF analysis spectrometer:

XRF analysis spectrometer:  Valuation by numbers:

Valuation by numbers: