Obowiązek informacyjny RODO – Kontrahenci.

1) Zakres danych: przetwarzamy następujące kategorie Państwa danych: dane identyfikacyjne (imię i nazwisko osób reprezentujących kontrahenta, nazwa podmiotu gospodarczego, NIP, REGON), dane kontaktowe (numer telefonu, adres poczty elektronicznej) oraz korespondencyjne (adres siedziby podmiotu gospodarczego, adres korespondencyjny), dane dot. zawartych umów, dane finansowe, numer rachunku bankowego;

2) Administrator: Administratorem Państwa danych osobowych jest DS Auto sp. z o.o. z siedzibą w Chrzanowie, 32-500 Chrzanów, ulica Szymanowskiego numer 2, NIP: 6282243187 oraz REGON: 121408687, wpisanej do Rejestru Przedsiębiorców Krajowego Rejestru Sądowego pod numerem KRS: 0000377003 (dalej jako „Spółka”);

3) Cele i podstawa przetwarzania: W związku z tym, że łączy Państwa umowa zawarta ze Spółką, Państwa dane osobowe są przetwarzane w następującym celu:

a) realizacji zawartej umowy (podstawa prawna: art. 6 ust 1 lit. b Rozporządzenia Parlamentu Europejskiego i Rady (UE) 2016/679 z dnia 27 kwietnia 2016 r. w sprawie ochrony osób fizycznych w związku z przetwarzaniem danych osobowych i w sprawie swobodnego przepływu takich danych oraz uchylenia dyrektywy 95/46/WE (ogólne rozporządzenie o ochronie danych), „RODO”);

b) udokumentowania zawartej umowy i jej rozliczenia, na podstawie przepisów prawa podatkowego, rachunkowego (podstawa prawna: art. 6 ust 1 lit. c RODO);

c) wewnętrznych celów administracyjnych Spółki, w tym statystyki i raportowania wewnętrznego Spółki będących realizacją naszego prawnie uzasadnionego interesu (podstawa prawna: art. 6 ust. 1 lit. f RODO);

d) archiwalnym (dowodowym) będącym realizacją naszego prawnie uzasadnionego interesu zabezpieczenia informacji na wypadek prawnej potrzeby wykazania faktów (podstawa prawna: art. 6 ust. 1 lit. f RODO);

e) w celu ewentualnego ustalenia, dochodzenia lub obrony przed roszczeniami będącego realizacją naszego prawnie uzasadnionego interesu (podstawa prawna: art. 6 ust. 1 lit. f RODO);

f) rozpatrywania reklamacji, w przypadku ich wniesienia, na sposób realizacji umowy łączącej Państwa ze Spółką (podstawa prawna: art. 6 ust. 1 lit. b RODO);

g) rozpatrywania skarg, w przypadku ich wniesienia, na jakość realizacji obowiązków wynikających z zawartej umowy i sposobu obsługi przez pracowników Spółki (podstawa prawna: art. 6 ust. 1 lit. b RODO).

5) Odbiorcy danych: odbiorcą Państwa danych osobowych będą: spółki Unimetal Rec sp.z o.o. oraz Unimetal Rec spółka z ograniczoną odpowiedzialnością sp.k..

6) Okres przechowywania: W przypadku przetwarzania danych osobowych na podstawie wyrażonych przez Państwa dobrowolnych zgód możemy przetwarzać dane do czasu, aż wycofają Państwo wyrażoną w tym zakresie zgodę lub ustalimy, że się zdezaktualizowały. Dane przetwarzane na podstawie prawnie uzasadnionego interesu administratora możemy przetwarzać do czasu wypełnienia prawnie uzasadnionych interesów Spółki stanowiących podstawę tego przetwarzania lub do czasu wniesienia przez Państwa sprzeciwu wobec takiego przetwarzania. Dane przetwarzane w pozostałym zakresie możemy przetwarzać przez okres nie dłuższy niż 6 lat.

7) Pouczenie o prawach: przysługuje Państwu prawo dostępu do treści swoich danych oraz prawo ich sprostowania, usunięcia, ograniczenia przetwarzania, prawo do przenoszenia danych, prawo wniesienia sprzeciwu wobec przetwarzania danych, prawo do cofnięcia zgody w dowolnym momencie bez podania przyczyny, bez wpływu na zgodność z prawem przetwarzania, którego dokonano na podstawie zgody przed jej cofnięciem;

8) Prawo do skargi: przysługuje Państwu prawo wniesienia skargi do Prezesa Urzędu Ochrony Danych Osobowych, gdy uznają Państwo, iż przetwarzanie danych osobowych Państwa dotyczących narusza przepisy RODO;

9) Prawo do sprzeciwu: w każdej chwili przysługuje Państwu prawo do wniesienia sprzeciwu wobec przetwarzania Państwa danych na podstawie prawnie uzasadnionego interesu, opisanego powyżej. Przestaniemy przetwarzać Państwa dane w tych celach, chyba że będziemy w stanie wykazać, że w stosunku do tych danych istnieją dla nas ważne prawnie uzasadnione podstawy, które są nadrzędne wobec Państwa interesów, praw i wolności, lub dane będą nam niezbędne do ewentualnego ustalenia, dochodzenia lub obrony roszczeń.

10) Państwa dane osobowe nie podlegają zautomatyzowanemu podejmowaniu decyzji, w tym profilowaniu związanym z automatycznym podejmowaniem decyzji;

11) Cofnięcie zgody: W przypadku przetwarzania danych osobowych na podstawie zgód w każdej chwili przysługuje Państwu prawo do wycofania swojej zgody poprzez bezpośredni kontakt ze Spółką w formie pisemnej na adres siedziby Spółki z dopiskiem „Dane osobowe”, bez podania przyczyny, a także bez wpływu na zgodność z prawem przetwarzania, którego dokonano na podstawie zgody przed jej cofnięciem. W przypadku skorzystania z tego prawa zaprzestaniemy przetwarzania danych w celu objętym uprzednio wyrażoną zgodą.

Phone number: +48 604 611 917

Phone number: +48 604 611 917  E-mail: dsautospzoo@wp.pl

E-mail: dsautospzoo@wp.pl A stationary point: YES

A stationary point: YES Getting from the customer: YES

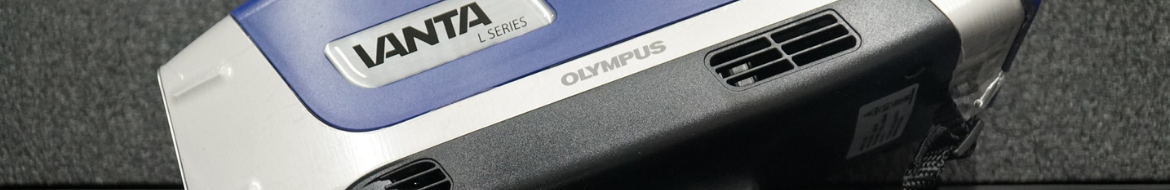

Getting from the customer: YES XRF analysis spectrometer: YES

XRF analysis spectrometer: YES Valuation by numbers: YES

Valuation by numbers: YES